The Levelized Cost of Hydrogen (LCOH) is one of the most common metrics used to benchmark the...

Solar Hydrogen: Business Development Insights for Optimal Sizing

This blog post provides a summary of the main findings from our recent research on optimal sizing for solar hydrogen systems.

We delve into the complexities of system optimization and explore different sizing ratios, drawing from our comprehensive study entitled "Assessing the Optimal Sizing of AC-linked Solar PV-PEM Systems for Off-Grid Hydrogen Production".

Click here to read the full paper in the International Journal of Hydrogen Energy

The Importance of Sizing in Solar Hydrogen Plants:

In the realm of complex energy systems, such as electrolytic hydrogen production plants supplied by renewable energy assets off-grid, the importance of sizing cannot be overstated. It goes beyond being just a term; it is a critical determinant of efficiency and profitability. This is especially true for solar hydrogen plants, where finding the optimal sizing is like solving a complex puzzle. A recent study led by Southern Light's founder, Felipe Gallardo, has shed light on this issue, offering insights into the optimal sizing of AC-linked solar PV-PEM systems and bridging the gap between theoretical knowledge and practical application.

Methodology: A Closer Look:

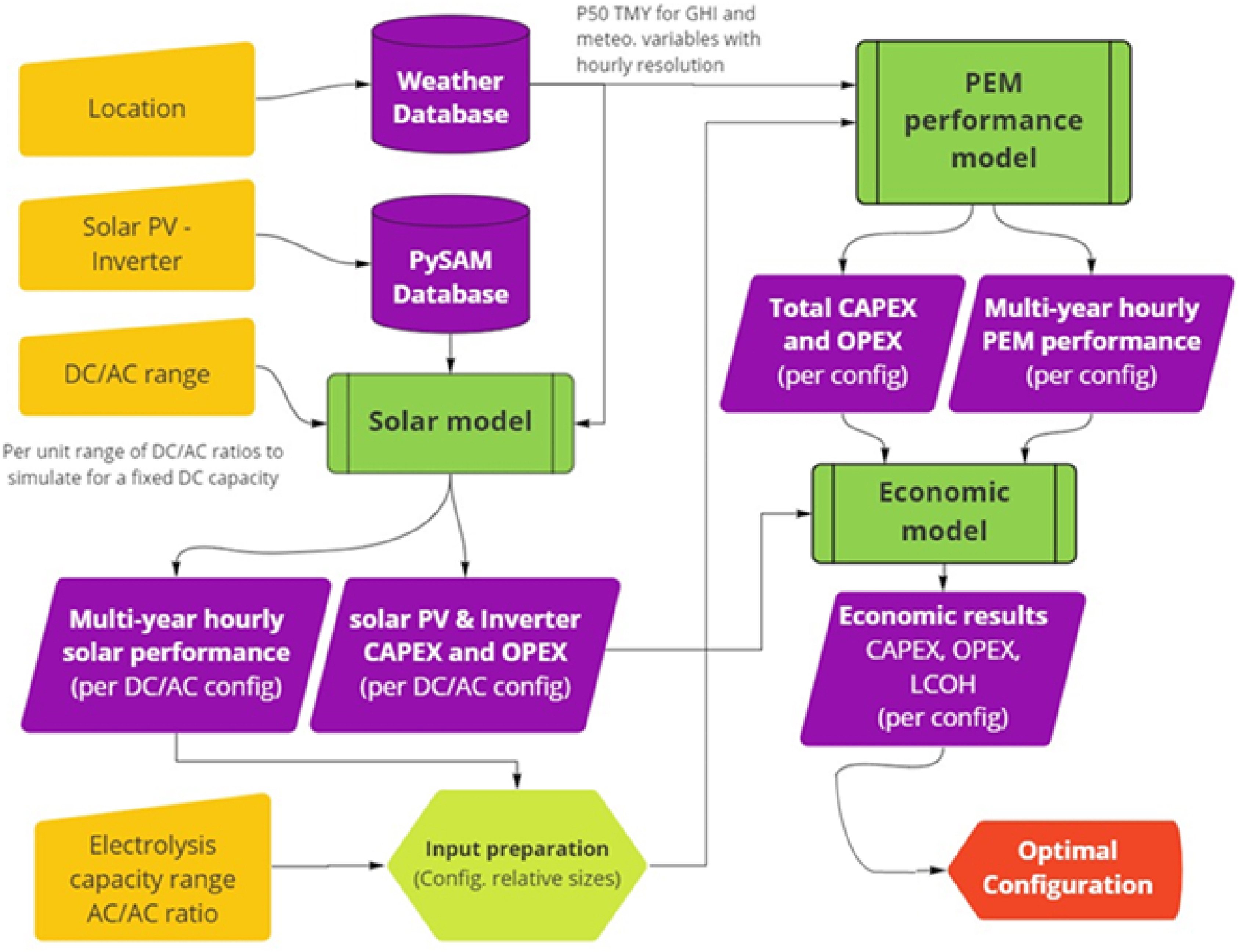

The research employed a systematic approach:

-

Data Collection: Extensive data was collected from a wide range of geographical locations, taking into account various variables such as solar irradiance, temperature, and other environmental factors. These locations included areas with exceptionally high solar radiation like the Atacama region in northern Chile, as well as regions where solar plants face challenges due to low plant factors, such as the northern United States.

-

Simulation: Employing advanced simulation tools powered by Southern Lights' exclusive algorithms, we conducted a thorough analysis of diverse solar PV-PEM system configurations in order to determine the most optimal sizing ratios. Our investigation delved into the correlation between the inverter output capacity of the solar plant and the rectifier's capacity of the electrolyzer plant, introducing the concept of AC/AC ratio. Furthermore, we took into account the variability of the solar plant's optimal DC/AC ratio and how its optimatility fluctuates when the primary objective shifts from electricity generation to hydrogen production. Our simulations encompassed hourly assessments, multi-year scenarios, degradation of components, and the dynamic efficiency of subsystems and auxiliaries.

-

Optimization: The study aimed to find the sweet spot where the Levelized Cost of Hydrogen (LCOH) is minimized without compromising system efficiency. It should be notice that optmizing LCOH is a well-accepted practice to find the best configurations when comparing plants which sole goal is to produce hydrogen. For projects with more complex business models combining different revenue streams, other optimization variables such as NPV or IRR should be looked at instead

Key Findings:

- The AC/AC ratio stands out as a pivotal metric for gauging efficiency. For instance, in Atacama, Chile, an optimal AC/AC ratio of around 1.2, paired with a DC/AC ratio of about 1.3, results in an LCOH of approximately 5.9 USD/kg.

- CAPEX and Production: Delving deeper, this ratio has profound implications for total CAPEX, production, and load factor. A higher AC/AC ratio essentially means amplifying the solar capacity upstream of the electrolyzer. Given that solar technology is mature and comparatively cost-effective against the electrolyzer, this strategy aims to maximize the operational hours or load factor of the more expensive electrolyzer.

- Balancing Costs and Load factors: The drive to elevate the sizing factor is a balancing act. On one side, there's the allure of increasing the solar capacity to boost the electrolyzer's load factor. On the other, this comes with an escalated solar CAPEX. Moreover, as the AC/AC ratio rises, the marginal benefit in terms of load factor enhancement diminishes.

- Cost Dynamics: A pivotal insight was the variance in the optimal solar DC/AC ratio by up to 54% when the focus shifted from energy cost to hydrogen cost.

- Seasonal Variability: The solar resource's seasonal variability plays a pivotal role in determining the AC/AC ratio. During winter, an optimally sized system might see the electrolyzer's load factor nearing 100% during solar hours. However, come summer, this could lead to overproduction. Developers must then decide whether to redirect this surplus energy to the grid, utilize it elsewhere, or curtail it. The study underscored the importance of location-specific solutions. In Fargo, N. Dakota, an AC/AC ratio of about 1.4 and a DC/AC ratio close to 1.8 was found optimal, resulting in an LCOH of nearly 9.7 USD/kg.

- A Key Variable for Business Development: In essence, the AC/AC factor isn't just a number—it's a strategic variable. It empowers developers to navigate the intricate maze of optimal sizing in solar hydrogen projects, striking a balance between efficiency, costs, and resource variability. In the picture below the optimal LCOH obtained are shown for different locations showing the variations in sizing ratios leading to optimality.

Implications for the Industry:

The Imperative need for Holistic Optimization when sizing: In the realm of large-scale solar hydrogen projects, consortium efforts often lead to a division of responsibilities, with different entities handling various subsystems. However, true optimization isn't about perfecting individual components in isolation.

Both AC/AC and DC/AC ratios, while internal, play pivotal roles in balancing CAPEX and hydrogen production. Treating the entire plant as a cohesive system and optimizing it as a unified entity ensures the minimum LCOH is achieved. Dividing and optimizing subsystems independently for example the solar plant in this case as if it was to be design to produce electricity only, can result in suboptimal configurations for hydrogen projects.

Conclusion:

Harnessing the potential of green hydrogen is a journey filled with challenges. But with the right knowledge, tools, and expertise, these challenges become stepping stones to a brighter, sustainable future. As the energy paradigm shifts, staying informed and leveraging state-of-the-art research is crucial. Southern Lights is at the forefront of this change, simplifying complexities and empowering developers to shape the future.

Looking to delve deeper into the subject? Access to the complete research paper published in the International Journal of Hydrogen Energy, which was the base of this blog post, for a more thorough exploration. Click here to read the full paper.

_________________________________________

About Southern Lights:

Southern Lights stands at the forefront of green hydrogen project development, offering a cutting-edge SaaS platform that seamlessly integrates hydrogen production processes, operational variables, and market dynamics. With a blend of advanced algorithms, and over a decade of domain expertise, Southern Lights empowers energy developers, consultants and researchers to navigate the complexities of this emerging field, ensuring optimized outcomes and sustained success.

Get in touch: felipe@southernlights.io